Preventing Weld Undercut: Proven Methods Every Welder Ought To Know

Preventing Weld Undercut: Proven Methods Every Welder Ought To Know

Blog Article

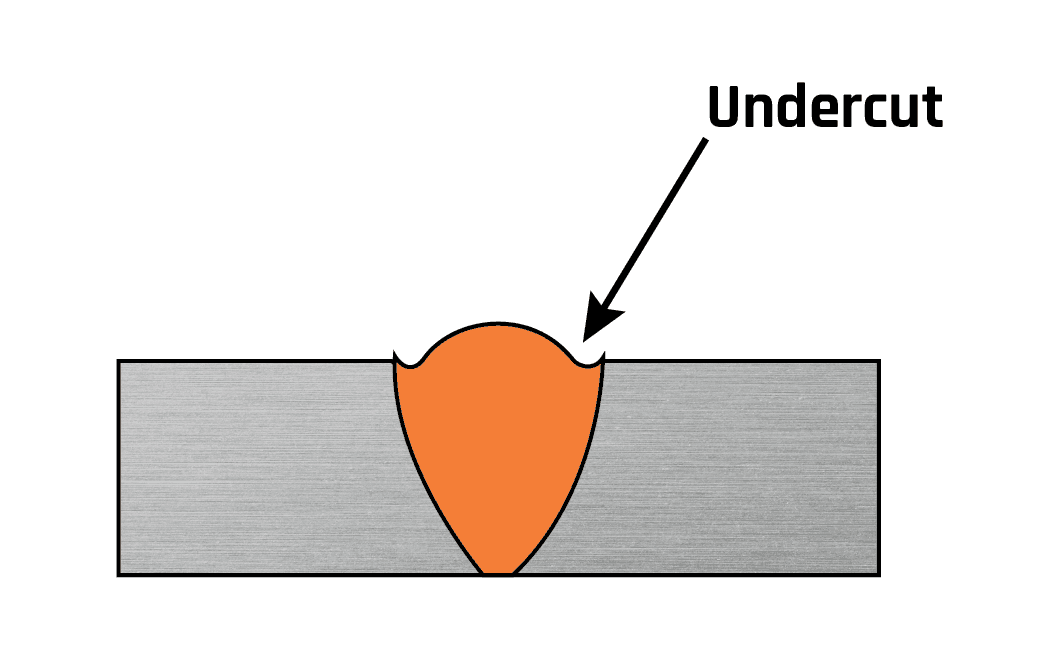

Understanding the Art of Welding: Exactly How to Stay Clear Of Undercut Welding Issues for Flawless Construction Outcomes

Effectiveness and accuracy are critical worldwide of welding, where even the slightest flaw can endanger the structural stability of a fabricated piece. One usual challenge that welders face is undercutting, an issue that can lead and deteriorate a weld joint to pricey rework. By understanding the origin creates of undercut welding and executing efficient strategies to avoid it, welders can raise their craft to new degrees of quality (Preventing weld undercut). In the pursuit of perfect construction outcomes, mastering the art of welding to avoid undercut problems is not simply an ability yet a necessity for those aiming for excellence in their job.

Comprehending Undercut Welding

To protect against undercut welding, welders need to ensure correct welding parameters, such as adjusting the current, voltage, travel speed, and preserving the correct electrode angle. By understanding the reasons of undercut welding and carrying out preventive actions, welders can attain premium, structurally sound welds.

Sources Of Undercut in Welding

Comprehending the aspects that add to damage in welding is vital for welders to generate top quality, structurally audio welds. Damaging takes place when the weld metal does not effectively fill the groove formed in between the base metal and the formerly transferred weld steel. A number of variables can lead to undercut in welding. One common cause is excessive warmth input. Welding at high temperature levels for extensive periods can result in the base metal melting even more than desired, leading to damage. Inadequate welding inaccurate or existing welding rate can additionally add to undercut. Not enough current might not offer sufficient heat to melt the base and filler metals adequately, while too much speed can stop proper combination, triggering undercut. Furthermore, inappropriate electrode angles or incorrect torch manipulation methods can develop areas of reduced weld steel deposition, promoting undercut. Understanding these causes and carrying out appropriate welding techniques can aid prevent undercutting issues, making sure solid and durable welds.

Techniques to avoid Undercutting

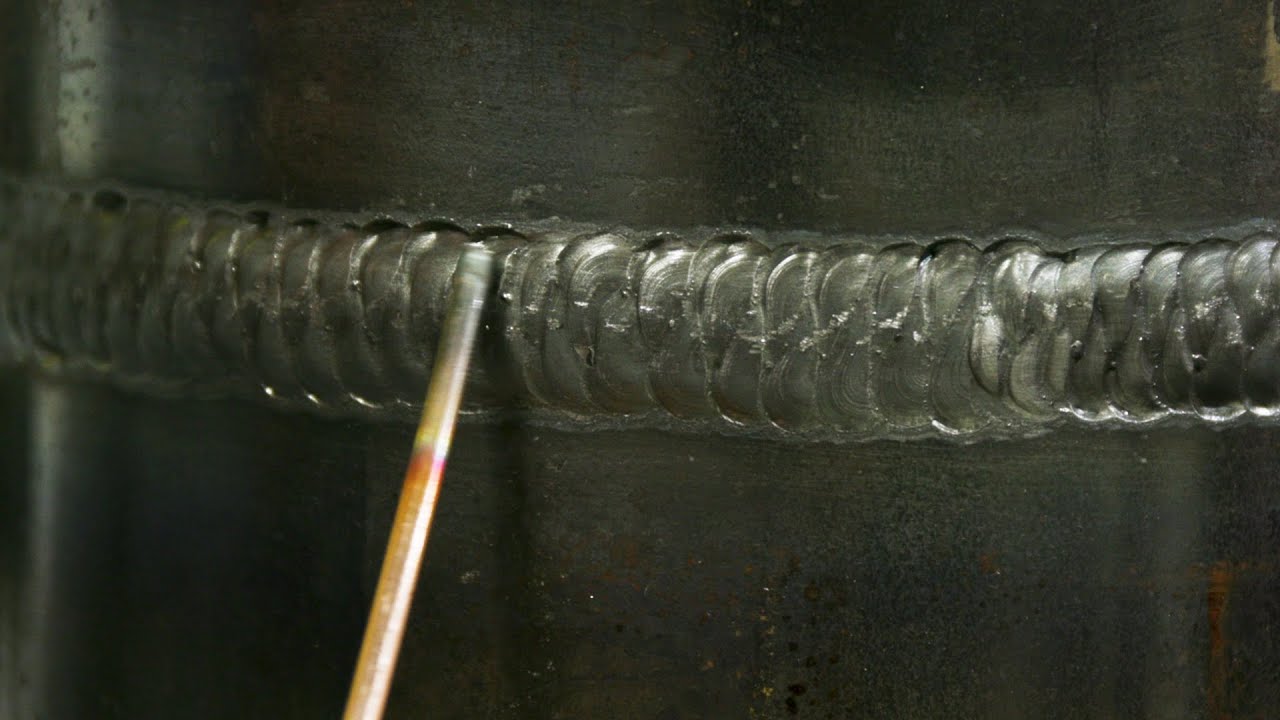

To reduce the threat of undercutting in welding, welders can employ tactical welding strategies focused on enhancing the high quality and stability of the weld joints. One reliable method is to readjust the welding specifications, such as voltage, present, and travel speed, to ensure correct warm input and deposition. Keeping an appropriate electrode angle and ensuring regular travel speed can likewise aid stop undercut. Furthermore, making use of the right welding method for the particular joint configuration, such as weave or stringer beads, can contribute to reducing undercutting. Preventing weld undercut.

Furthermore, appropriate joint prep work, including making sure clean base products without impurities and utilizing the suitable welding consumables, is important in avoiding undercut issues. Employing back-step welding strategies and regulating the weld bead account can also aid disperse heat uniformly and lessen the danger of undercut. Regular inspection of the weld joint during and after welding, as well as executing high quality assurance procedures, can aid in dealing with and discovering damaging concerns without delay. By implementing these strategies diligently, welders can accomplish perfect construction results with marginal undercut problems.

Value of Correct Welding Specifications

Choosing and keeping appropriate welding parameters is necessary for achieving successful welds with very little flaws. Welding specifications refer to variables such as voltage, existing, take a trip rate, electrode angle, and shielding gas flow rate that directly influence the welding process. These specifications should be thoroughly readjusted based on the sort of product being welded, its density, and the welding method employed.

Proper welding criteria make sure the ideal amount of warm is related to thaw the base metals and filler product evenly. If the parameters are set too high, it can result in excessive warm input, causing burn-through, spatter, or distortion. On the various other hand, if the criteria are as well low, insufficient combination, lack of infiltration, or damaging might happen.

Quality Control in Welding Operations

Verdict

To conclude, grasping the art of welding needs a detailed understanding of undercut welding, its reasons, and strategies to stop it. By ensuring appropriate welding criteria and executing quality control practices, remarkable manufacture outcomes can be accomplished. It is vital for welders to regularly strive for excellence in their welding operations to stay clear of undercut problems and produce high-grade welds.

Undercut welding, an usual published here issue in welding procedures, occurs when the weld steel doesn't appropriately fill up the groove and leaves a groove or anxiety along the welded joint.To stop undercut welding, welders ought to ensure correct welding specifications, such as adjusting the current, voltage, traveling speed, and keeping the correct electrode angle. Insufficient welding existing or incorrect welding rate can likewise you could look here add to damage.To reduce the risk of damaging in welding, welders can employ critical welding techniques intended at enhancing the high quality and stability of the weld joints.In verdict, understanding the art of welding requires a comprehensive understanding of undercut welding, its reasons, and strategies to avoid it.

Report this page